Vitalis Phyto2

Developed a portable, battery-powered field test device combining chromatography and computer vision to assess crop maturity and phytochemical composition in industrial agricultural environments.

Portable Crop Maturity Assessment via Chemistry & Vision

Category

professional

Company

Vitalis

Status

Completed

Why we built it

In agriculture and extraction workflows, harvest timing is everything.

Crop maturity is not determined by a single marker. It depends on the relative composition and ratios of phytochemicals, how those compounds evolve over time, and how they vary by species and growing conditions. Existing approaches relied on lab-based analysis or subjective judgment, both of which were slow, expensive, and poorly suited for field use.

The goal was to build a field-deployable system that could rapidly characterize phytochemical profiles on-site and translate them into a clear signal of maturity and yield readiness.

What I built

I designed and integrated an end-to-end sensing and analysis device, spanning physical chemistry, perception, embedded systems, and cloud infrastructure.

This was a true systems-integration effort, requiring tight coordination between optics, mechanics, electronics, firmware, perception algorithms, and data infrastructure.

Core Components

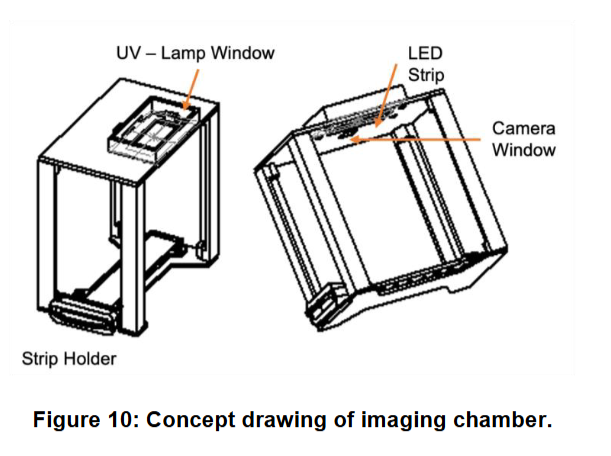

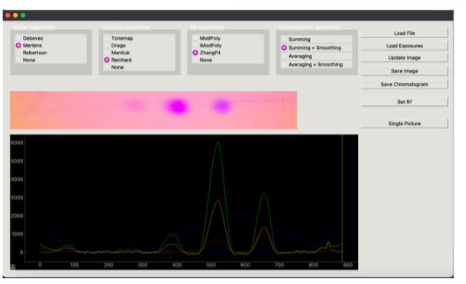

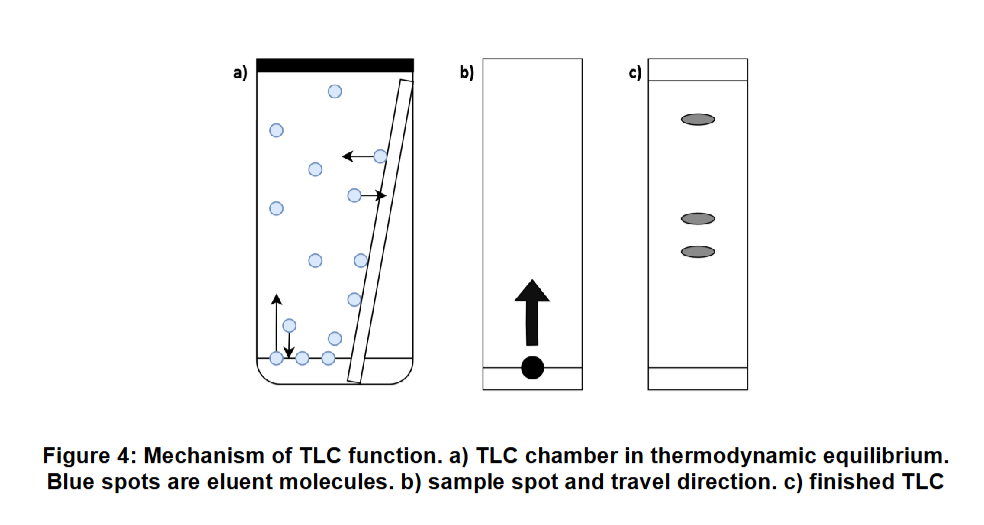

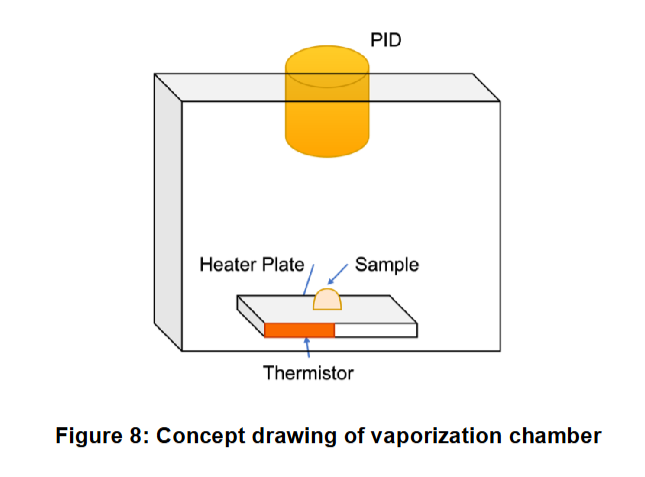

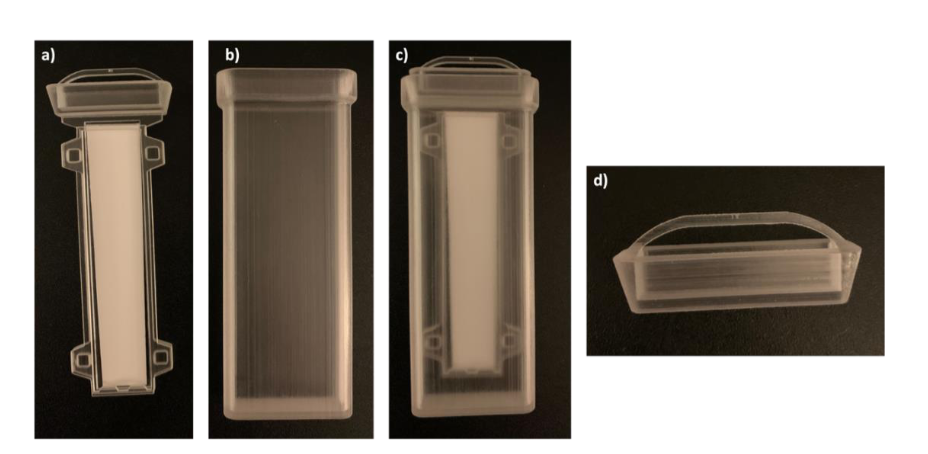

- Thin-layer chromatography (TLC) module: To separate phytochemical compounds for visualization.

- Hyperspectral and optical imaging: To capture chemical signatures and spatial distribution.

- Computer vision pipelines: To detect, segment, and quantify chromatographic bands.

- Chemical labeling logic: To map visual features to known phytochemical identities and ratios.

- ML-based classification: To infer crop maturity state based on species-specific priors.

- On-device calibration and control: To ensure repeatable field measurements.

- Cloud-assisted processing: For heavier analysis and model updates.

- Wireless logging and UI: To surface results and support product workflows.

The Analysis Pipeline

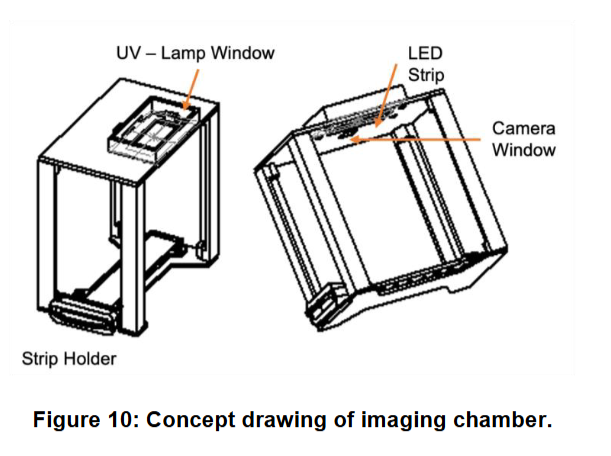

At a high level, the device workflow translates complex chemical patterns into simple field decisions:

- 1. Capture phytochemical samples from plant material.

- 2. Separate compounds using TLC.

- 3. Image the resulting chemical patterns under controlled illumination.

- 4. Quantify compound presence and ratios via computer vision.

- 5. Combine measurements with species-specific knowledge and historical data.

- 6. Output a maturity and harvest-readiness signal.

This allowed non-experts in the field to make decisions that previously required lab analysis.

On-device analysis and decision interface

Phytochemical Separation & Sensing

The core challenge was translating variable chemical separations into consistent digital features.

Integration of sample prep and vision-based analysis

Quantifying phytochemical bands through feature extraction

The system combined multi-wavelength illumination with classical CV techniques (thresholding, segmentation, and band-ratio analysis) to identify compound presence. By comparing these against known libraries (learned priors), we could determine the exact point on the compound-evolution curve, predicting the optimal harvest window.

Productization and Field Readiness

Beyond the core sensing pipeline, I worked toward productizing the system:

- Ruggedized Design: Designed portable enclosures suitable for harsh field environments.

- Power & Connectivity: Integrated battery power, onboard compute, and wireless logging.

- Workflow-driven UI: Built early operator UIs to guide non-technical users through the sampling process.

- Environmental Robustness: Ensured reliable operation across variable lighting and temperature conditions.

What I learned

This project reinforced the complexity of translating lab science into field-ready systems.

Lab Science vs. Field Reality

I learned how tightly coupled chemistry, optics, and perception become once you leave controlled environments. Small mechanical or lighting variations cascade directly into model performance. Designing calibration, isolation, and validation into the system from the start was critical.

Systems Integration

More broadly, this work deepened my appreciation for systems integration. The hardest problems were not individual subsystems, but the interfaces between them, and ensuring the full stack behaved predictably under real-world constraints.

Technologies Used

Key Outcomes

- •Productized lab-grade chemical analysis into a field-deployable ruggedized device

- •Automated phytochemical characterization using on-device CV pipelines

- •Enabled non-expert operators to make high-stakes harvest decisions via clear UI signals